Search form

北美

- 美國 English-en

- 加拿大 English-en

- 墨西哥 Spanish-es

歐洲

- 法國 French-fr

- 德國 Deutsch-de

- 意大利 Italian-it

- 意大利 Castellano-cas

- 英國/愛爾蘭 English-en-gb

- 所有其他歐洲國家 English-en-gb

亞洲

- 中國 中文-簡體

- 所有其他東亞國家及地區 中文-簡體

- 印度 English-en-gb

- 所有其他印度次大陸國家 English-en-gb

中南美洲

- 加勒比地區 English-en

- 南美和中美 Spanish-es

非洲和中東

- 所有非洲國家 English-en-gb

- 以色列 English-en-gb

- 所有中東國家 English-en-gb

環太平洋地區

- 澳大利亞/新西蘭 English-en-gb

- 所有其他環太平洋國家 English-en

There are no products in your shopping cart.

| 0 Items | Total: ¥0.00 |

庫存彈簧公差和工程注釋

英制/公制換算

Force

| To Convert Newtons to | Kilogrammes | Pounds |

| Multiply by | 0.102 | 0.22487 |

| To Convert Kilogrammes to | Newtons | Pounds |

| Multiply by | 9.807 | 2.2046 |

| To Convert Pounds to | Newtons | Kilogrammes |

| Multiply by | 4.448 | 0.4536 |

Rate

| To Convert kg/mm to | lb/in | N/mm |

| Multiply by | 55.998 | 9.807 |

| To Convert lb/in to | kg/mm | N/mm |

| Multiply by | 0.017858 | 0.175133 |

| To Convert N/mm to | kg/mm | lb/in |

| Multiply by | 0.101968 | 5.7099 |

Length

| To Convert Inches to | Meters | Feet | Millimetres |

| Multiply by | 0.0254 | 0.08333 | 25.4 |

| To Convert Millimetres to | Meters | Feet | Inches |

| Multiply by | 0.001 | 0.003281 | 0.0393701 |

Stock Compression Spring and Extension Spring Engineering Notes and Tolerances

一般說明

旋向

左旋或右旋由力司百靈決定

壓縮彈簧端口

- 兩端閉合且磨平(垂直度在3°以內):標準彈簧(LC、LCM)、重型彈簧(LHC)、高壓彈簧(LHP)、DIN-PLUS第1部分

- 兩端閉合且不磨平:Bantam微型壓縮彈簧(CB、CBM)、儀表彈簧(CI、CIM)、微壓力彈簧(LP)、DIN-PLUS第2部分

拉伸彈簧端口

- 任意位置的拉環,設計符合DIN 2097標準的LEM產品除外

- 線圈開口約為一個鋼絲直徑。

壓縮彈簧標準件壓縮外徑(OD)公差*

Imperial/Inch

| .025" | to | .039” | ± | .002” |

| .040” | to | .118” | ± | .003” |

| .120” | to | .250” | +.003”/–.005” | |

| .251” | to | .299” | ± | .005” |

| .300” | to | .500” | ± | .008” |

| .501” | to | .850” | ± | .015” |

| .851” | to | 1.125” | ± | .020” |

| 1.126” | to | 1.218” | ± | .025” |

| 1.250” | to | 1.460” | ± | .030” |

| 1.480” | to | 1.687” | ± | .040” |

| 1.937" | to | 2.000" | ± | .055" |

Metric

| 0.64mm | to | 0.99mm | ± | .05mm |

| 1.02mm | to | 3.00mm | ± | .08mm |

| 3.05mm | to | 6.10mm | +.08mm/– .13mm | |

| 6.38mm | to | 7.59mm | ± | .13mm |

| 7.62mm | to | 12.70mm | ± | .20mm |

| 12.73mm | to | 21.59mm | ± | .38mm |

| 21.62mm | to | 28.58mm | ± | .51mm |

| 28.60mm | to | 30.94mm | ± | .64mm |

| 31.75mm | to | 37.08mm | ± | .76mm |

| 37.59mm | to | 42.85mm | ± | 1.02mm |

| 49.20mm | to | 50.80mm | ± | 1.40mm |

彈簧剛度:±10%;壓并高度公差:+5%,無下限

*除非注明符合DIN 2098的要求

此外徑表不適用于Lite微壓力、HEFTY模具、REDUX波形或MIL-SPEC美國軍標

英制/英寸 |

||||

|---|---|---|---|---|

| .201" | 到 | .300" | ± | .008" |

| .301" | 到 | .500" | ± | .010" |

| .501" | 到 | .850" | ± | .020" |

| .851" | 到 | 1.125" | ± | .025" |

| 1.126" | 到 | 1.460" | ± | .030" |

| 1.461" | 到 | 1.687" | ± | .040" |

| 1.688" | 到 | 1.937" | ± | .055" |

| 1.938" | 到 | 2.375" | ± | .070" |

| 2.376" | 到 | 2.875" | ± | .090" |

公制 |

||||

|---|---|---|---|---|

| 5.11mm | 到 | 7.62mm | ± | .20mm |

| 7.65mm | 到 | 12.70mm | ± | .25mm |

| 12.73mm | 到 | 21.59mm | ± | .51mm |

| 21.62mm | 到 | 28.58mm | ± | .64mm |

| 28.60mm | 到 | 37.08mm | ± | .76mm |

| 37.11mm | 到 | 42.85mm | ± | 1.02mm |

| 42.88mm | 到 | 49.20mm | ± | 1.40mm |

| 49.23mm | 到 | 60.33mm | ± | 1.78mm |

| 60.35mm | 到 | 73.03mm | ± | 2.29mm |

彈簧剛度:± 10%

英制/英寸 |

||||

|---|---|---|---|---|

| .120" | 到 | .240" | ± | .005" |

| .300" | 到 | .500" | ± | .008" |

| .550" | 到 | .850" | ± | .015" |

公制 |

||||

|---|---|---|---|---|

| 3.05mm | 到 | 6.10mm | ± | .13mm |

| 7.62mm | 到 | 12.70mm | ± | .20mm |

| 13.97mm | 到 | 21.59mm | ± | .38mm |

彈簧剛度:± 10%

壓并高度公差:最大,無下限

英制/英寸 |

||||

|---|---|---|---|---|

| .063" | 到 | .098" | ± | .004" |

| .109" | 到 | .299" | ± | .005" |

| .300" | 到 | .500" | ± | .010" |

| .501" | 到 | .850" | ± | .015" |

| .851" | 到 | 1.125" | ± | .020" |

| 1.126" | 到 | 1.250" | ± | .030" |

| 1.251" | 到 | 1.500" | ± | .040" |

| 1.501" | 到 | 1.750" | ± | .050" |

| 1.751" | 到 | 2.000" | ± | .055" |

公制 |

||||

|---|---|---|---|---|

| 1.60mm | 到 | 2.50mm | ± | .10mm |

| 2.77mm | 到 | 7.59mm | ± | .13mm |

| 7.62mm | 到 | 12.70mm | ± | .25mm |

| 12.73mm | 到 | 21.59mm | ± | .38mm |

| 21.62mm | 到 | 28.58mm | ± | .51mm |

| 28.60mm | 到 | 31.75mm | ± | .76mm |

| 31.78mm | 到 | 38.10mm | ± | 1.02mm |

| 38.13mm | 到 | 44.45mm | ± | 1.27mm |

| 44.48mm | 到 | 50.80mm | ± | 1.40mm |

彈簧剛度:± 10%

*除非注明符合DIN 2097標準或MIL-SPEC美國軍標

英制/英寸 |

||||

|---|---|---|---|---|

| .120" | 到 | .240" | ± | .005" |

| .300" | 到 | .500" | ± | .008" |

| .650" | 到 | 1.000" | ± | .015" |

公制 |

||||

|---|---|---|---|---|

| 3.05mm | 到 | 6.10mm | ± | .13mm |

| 7.62mm | 到 | 12.70mm | ± | .20mm |

| 16.51mm | 到 | 25.40mm | ± | .38mm |

彈簧剛度:± 10%

拉環位置:在22°以內

拉環開口的相對位置在出廠時是可選的

扭轉技術備注和公差

一般說明

-

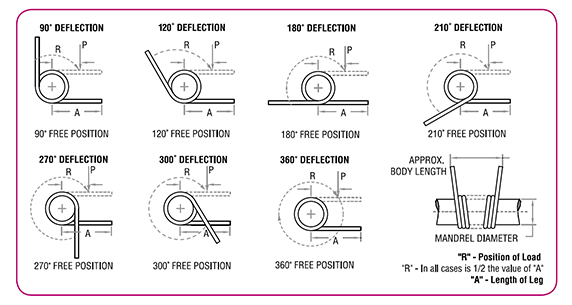

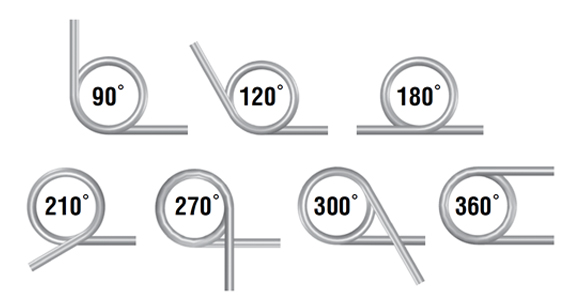

腿的長度在下面的草圖中顯示為“A”。

-

請注意:“R”(以英寸為單位的半徑)施加的力始終為“A”(腿長)的1/2。支腿的虛線表示加載位置,在“R”(半徑)處將達到“T”(扭矩)值。

-

要將扭矩值轉換為直接荷載:使用公式-P=T/R P=半徑處施加的荷載(R)T=扭矩示例:編號LTL 012A 01,R=0.187的荷載是什么?使用P=T/R=.050/.187=.267磅。

-

為了計算所列以外的扭矩值(端部位置),可以使用成正比的方法。示例:編號LTL 012 A 01。90°偏轉時,目錄列表中所示的扭矩為.050 in-lbs;因此,45°的扭矩為0.025 英寸-磅。

-

荷載檢查-應始終在半徑(“R”值)處檢查荷載

-

芯軸尺寸:通常,扭轉彈簧用于芯軸(軸或芯軸)上。“建議的芯軸尺寸,英寸”一欄允許以下示例中所示的各種位移有大約10%的間隙。如果您需要更大的位移,我們建議適當減小芯軸尺寸。

-

風向:良好的設計要求扭轉彈簧應在纏繞線圈的方向上使用。訂購時,確保選擇LTL(左旋向)或LTR(右旋向)用于所需的應用。

扭轉外徑(OD)公差

Imperial/Inch

| .093” | to | .125” | ± | .004” |

| .126” | to | .200” | ± | .005” |

| .201” | to | .300” | ± | .007” |

| .301” | to | .410” | ± | .010” |

| .411” | to | .500” | ± | .013” |

| .501” | to | .700” | ± | .015” |

| .701” | to | .875” | ± | .020” |

| .876” | to | 1.125” | ± | .025” |

| 1.126” | to | 1.218” | ± | .030” |

| 1.219” | to | 1.250” | ± | .035” |

| 1.251" | to | 1.360" | ± | .040" |

| 1.361" | to | 1.520" | ± | .045" |

| 1.521" | to | 1.750" | ± | .050" |

| 1.751" | to | 2.000" | ± | .055" |

| Over 2.000" | ± | .060" |

Metric

| 2.36mm | to | 3.17mm | ± | .10mm |

| 3.18mm | to | 5.08mm | ± | .13mm |

| 5.09mm | to | 7.62mm | ± | .18mm |

| 7.63mm | to | 10.41mm | ± | .26mm |

| 10.42mm | to | 12.70mm | ± | .33mm |

| 12.71mm | to | 17.78mm | ± | .38mm |

| 17.79mm | to | 22.23mm | ± | .51mm |

| 22.24mm | to | 28.58mm | ± | .64mm |

| 28.59mm | to | 30.94mm | ± | .76mm |

| 30.95mm | to | 31.75mm | ± | .89mm |

| 31.76mm | to | 34.54mm | ± | 1.02mm |

| 34.55mm | to | 38.60mm | ± | 1.14mm |

| 38.61mm | to | 44.45mm | ± | 1.27mm |

| 44.46mm | to | 50.80mm | ± | 1.40mm |

| Over 50.80mm | ± | 1.52mm |

Stock REDUX Wave Spring Engineering Notes and Tolerances

扭矩:±10%

自由位置公差:

總共3到10圈(包括±10°)

總共11到20圈(包括±15°)

REDUX波形彈簧技術備注和公差

一般說明

-

REDUX波形彈簧標準件由17-7PH不銹鋼材料制成

-

最高工作溫度為650華氏度

-

標稱載荷是工作高度處的近似力。請注意,如果彈簧壓縮到低于工作高度,則可能需要一組彈簧。

-

匝數包括一個連續線圈;波浪之間沒有焊接或粘合劑。

-

端部為波形。如有特殊需求也可按定制產品操作制作為端部平圈。

REDUX波形彈簧標準件公差

剛度:±25%

外徑和內徑僅供參考。REDUX波形彈簧的制造可在規定的配合孔直徑和桿直徑下工作。

.png)

Sign Up/Log In

Sign Up/Log In

蘇公網安備32059002002461號

蘇公網安備32059002002461號