材料標(biāo)準(zhǔn)可能有所不同,或由Lee Spring根據(jù)國(guó)際上等同的標(biāo)準(zhǔn)自行決定。

Search form

北美

- 美國(guó) English-en

- 加拿大 English-en

- 墨西哥 Spanish-es

歐洲

- 法國(guó) French-fr

- 德國(guó) Deutsch-de

- 意大利 Italian-it

- 意大利 Castellano-cas

- 英國(guó)/愛爾蘭 English-en-gb

- 所有其他歐洲國(guó)家 English-en-gb

亞洲

- 中國(guó) 中文-簡(jiǎn)體

- 所有其他東亞國(guó)家及地區(qū) 中文-簡(jiǎn)體

- 印度 English-en-gb

- 所有其他印度次大陸國(guó)家 English-en-gb

中南美洲

- 加勒比地區(qū) English-en

- 南美和中美 Spanish-es

非洲和中東

- 所有非洲國(guó)家 English-en-gb

- 以色列 English-en-gb

- 所有中東國(guó)家 English-en-gb

環(huán)太平洋地區(qū)

- 澳大利亞/新西蘭 English-en-gb

- 所有其他環(huán)太平洋國(guó)家 English-en

There are no products in your shopping cart.

| 0 Items | Total: ¥0.00 |

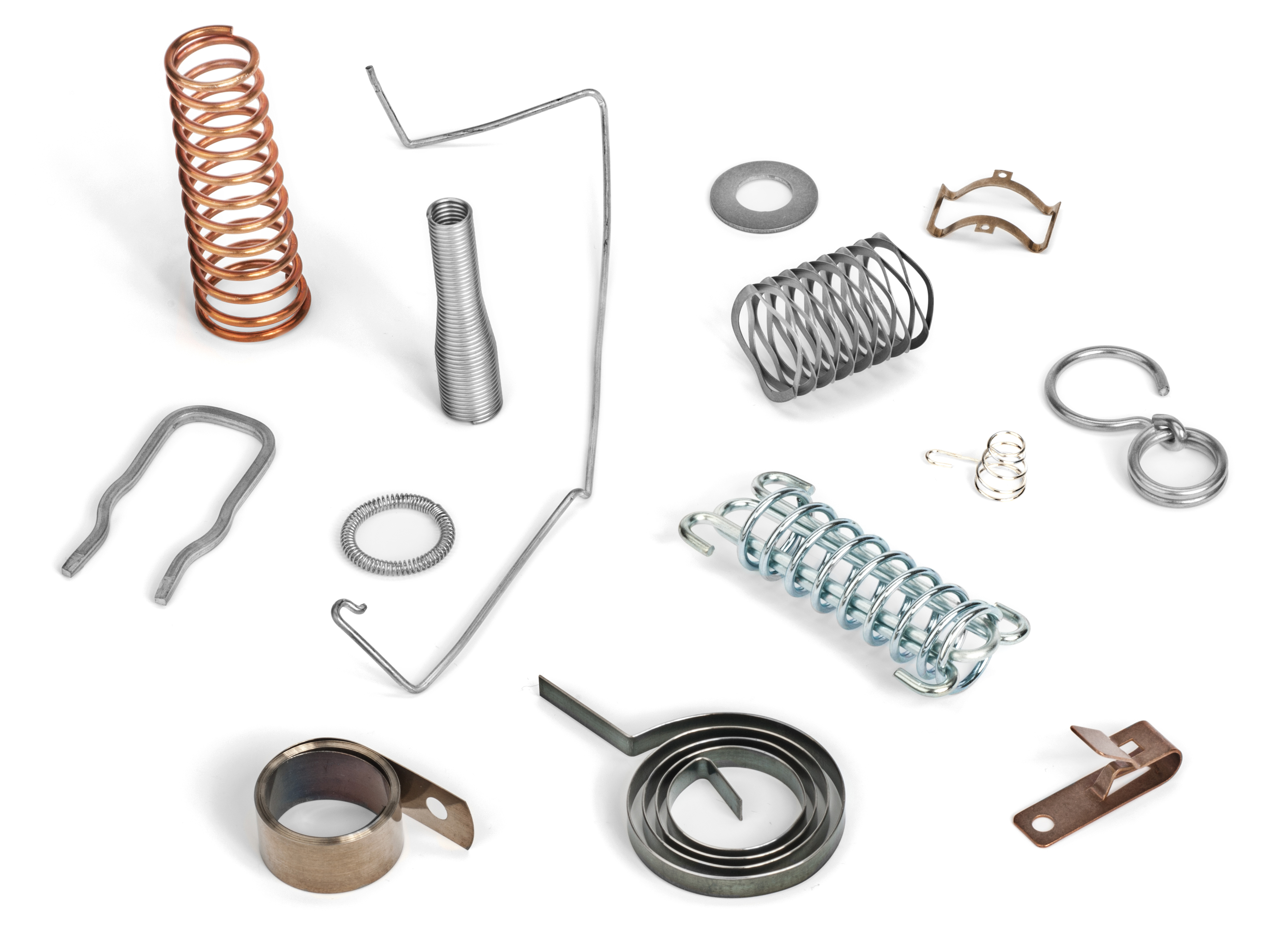

材料,后處理和電鍍

除了彈簧標(biāo)準(zhǔn)件之外,力司百靈還提供不同材料的彈簧定制件。在不同的應(yīng)用中,正確的材料可以使彈簧的性能完全不同。選擇材料一般會(huì)考慮到工作溫度,耐腐蝕性能要求以及彈簧參數(shù)。力司百靈的工程師,會(huì)根據(jù)您的實(shí)際使用情況,推薦給您最合適的彈簧材料。

銅合金

鎳合金

?

| 力司百靈彈簧標(biāo)準(zhǔn)件系列材料 | ||||||||

|---|---|---|---|---|---|---|---|---|

| 彈簧標(biāo)準(zhǔn)件系列 | 琴鋼絲 | 不銹鋼 | Elgiloy埃爾吉洛伊耐蝕非磁合金 | 油淬火 | 鉻硅 | 鈹銅 | Ultem | |

| 壓縮彈簧 | LeeP合成塑料 | ? | ? | ? | ? | ? | ? | X |

| BANTAM? 迷你系列 | ? | ? | X | ? | ? | ? | ? | |

| 儀表系列 | X | X | ? | ? | ? | ? | ? | |

| Lite Pressure?微壓力系列 | ? | SS316 | ? | ? | ? | ? | ? | |

| 標(biāo)準(zhǔn)件系列 | X | X | ? | ? | ? | ? | ? | |

| 重負(fù)荷系列 | X | X | ? | X | ? | ? | ? | |

| 高強(qiáng)度系列 | ? | 17-7 PH | ? | ? | ? | ? | ? | |

| REDUX ? 波形系列 | ? | 17-7 PH | ? | ? | ? | ? | ? | |

| HEFTY? 模具彈簧 | X | ? | ? | ? | X | ? | ? | |

| DIN-Plus系列 | X^ | X^ | ? | ? | ? | ? | ? | |

| 拉伸彈簧 | X | X | ? | ? | ? | ? | ? | |

| 扭轉(zhuǎn)彈簧 | X | X | ? | ? | ? | ? | ? | |

| 碟形彈簧 | ? | 300 Series | ? | ? | ? | ? | ? | |

| 恒力彈簧 | ? | 301 | ? | ? | ? | ? | ? | |

| 電池彈簧 | X | ? | ? | ? | ? | X | ? | |

| 可變長(zhǎng)度拉伸彈簧 | X | 302 | ? | ? | ? | ? | ? | |

| 彈簧組合套裝 | X | X | ? | ? | ? | ? | ? | |

| 掛鉤 | ? | X | ? | ? | ? | ? | ? | |

| 美國(guó)軍標(biāo)壓縮彈簧 | X* | 302 DFARS | ? | ? | ? | ? | ? | |

| 美國(guó)軍標(biāo)拉伸彈簧 | X* | 302 DFARS | ? | ? | ? | ? | ? | |

*無鍍層琴鋼絲(參考標(biāo)準(zhǔn) ASTM A228)或預(yù)鍍鎘琴鋼絲或預(yù)鍍鋅琴鋼絲

X^近似于歐盟EN 10270標(biāo)準(zhǔn)

材料屬性

High Carbon Steels

| Material | Commercially Available Specification | Nominal Chemistry | Density (lb/in3) | Minimum Tensile Strength (psi x 103) | Modulus of Elasticity (E)(psi x 106) | Modulus in Torsion (G)(psi x 106) | Maximum Operating Temperature | Description & Primary Use |

|---|---|---|---|---|---|---|---|---|

Oil Tempered MB |

ASTM A229 | C 0.55 - 0.85%, Mn 0.30 - 1.20% | 0.28 | Class I: 165 - 293, Class II: 191 - 324 | 30 | 11.5 | 250 °F | General purpose spring wire for average stress applications. Highly magnetic. Often used for larger wire sizes when Music Wire is not available. |

Hard Drawn MB |

ASTM A227 | C 0.45 - 0.85%, Mn 0.30 - 1.30% | 0.28 | Class I: 147 - 283, Class II: 171 - 324 | 30 | 11.5 | 250 °F | General purpose spring wire for low to average stress applications. Cold drawn to desired properties. Highly magnetic. |

Music Wire |

ASTM A228 | C 0.70 - 1.00%, Mn 0.20 - 0.70% | 0.28 | 230 - 399 | 30 | 11.5 | 250 °F | High quality spring wire that is cold drawn with good surface finish. Highly magnetic. Generally good fatigue life due to high tensile strength. |

Alloy Steels

| Material | Commercially Available Specification | Nominal Chemistry | Density (lb/in3) | Minimum Tensile Strength (psi x 103) | Modulus of Elasticity (E)(psi x 106) | Modulus in Torsion (G)(psi x 106) | Maximum Operating Temperature | Description & Primary Use |

|---|---|---|---|---|---|---|---|---|

Oil Tempered Chrome Vanadium |

ASTM A231 | C 0.48 - 0.53%, V 0.15 Min %, Mn 0.70 - 0.90%, Cr 0.80 - 1.10% | 0.28 | 190 - 300 | 30 | 11.5 | 425 °F | Alloy steel spring wire used for shock loads and moderately elevated temperatures. Highly magnetic. Available in Valve Spring quality in accordance with ASTM A232. |

Oil Tempered Chrome Silicon |

ASTM A401 | C 0.51 - 0.59%, Cr 0.60 - 0.80%, Si 1.20 - 1.60% | 0.28 | 224 - 300 | 30 | 11.5 | 475 °F | Alloy steel spring wire used for shock loads and moderately elevated temperatures. Highly magnetic. Available in Valve Spring quality in accordance with ASTM A877. |

Stainless Steels

| Material | Commercially Available Specification | Nominal Chemistry | Density (lb/in3) | Minimum Tensile Strength (psi x 103) | Modulus of Elasticity (E)(psi x 106) | Modulus in Torsion (G)(psi x 106) | Maximum Operating Temperature | Description & Primary Use |

|---|---|---|---|---|---|---|---|---|

Stainless Steel 17-7 PH |

AMS 5678 | Cr 16.0 - 18.0%, Ni 6.5 - 7.7%, Al 0.75 - 1.5% | 0.28 | Cond. CH900: 230 - 343 | 29.5 | 11 | 650 °F | Improved strength over 300 Series stainless steels with similar heat and corrosion resistance. Slightly magnetic. Material is precipitation hardened after spring fabrication to achieve desired properties. |

Stainless Steel 316 |

ASTM A313 | Cr 16.5 - 18.0%, Ni 10.5 - 13.5%, Mo 2.0 - 2.5% | 0.29 | 125 - 245 | 28 | 10 | 550 °F | General heat resistant spring wire and better corrosion resistance than Type 302/204. Slightly magnetic. Often used in marine applications, resists chloride attack. |

Stainless Steel 302/304 |

ASTM A313 | Cr 17.0 - 20.0%, Ni 8.0 - 10.5% | 0.29 | 130 - 325 | 28 | 10 | 550 °F | General purpose corrosion and heat resistant spring wire. Slightly magnetic. Type 304 has less carbon than Type 302, however considered commercially equivalent for stock springs. |

Copper Alloys

| Material | Commercially Available Specification | Nominal Chemistry | Density (lb/in3) | Minimum Tensile Strength (psi x 103) | Modulus of Elasticity (E)(psi x 106) | Modulus in Torsion (G)(psi x 106) | Maximum Operating Temperature | Description & Primary Use |

|---|---|---|---|---|---|---|---|---|

Monel K 500 |

QQ-N-286 | Ni 63.0 min%, Cu 27.0 - 33.0%, Al 2.3 - 3.1% | 0.31 | 160 - 200 | 26 | 9.5 | 550 °F | Similar corrosion and heat resistance to Monel 400 with better strength. Good for subzero and cryogenic applications. |

Monel 400 |

AMS 7233 | Ni 63.0 min%, Cu 28.0 - 34.0% | 0.32 | 145 - 180 | 26 | 9.5 | 450 °F | Nickel-copper alloy spring wire with good corrosion resistance at moderately elevated temperatures. Good mechanical properties for subzero temperature applications. Generally resistant to hydrofluoric, sulfuric, and hydrochloric acids. Typical for marine and chemical processing applications. |

Brass |

ASTM B134 | Cu 68.5 - 71.5%, Zn 28.5 - 31.5% | 0.31 | 120 min | 16 | 6 | 200 °F | Good combination of strength and ductility for cold working. Properties based on 70-30 Spring Brass (C26000) sub-type. Used in fresh water and seawater applications. |

Beryllium Copper |

ASTM B197 | Cu 98.0%, Be 1.8 - 2.0% | 0.30 | 160 - 230 | 18.5 | 7 | 400 °F | Non-ferrous spring wire with good corrosion resistance and electrical conductivity. Improved strength over phosphor bronze and non-magnetic. Material is precipitation hardened after spring fabrication to achieve desired properties. |

Phosphor Bronze |

ASTM B159 | Cu 94.0 - 96.0%, Sn 4.0 - 6.0% | 0.32 | 105 - 145 | 15 | 6.25 | 200 °F | Non-ferrous spring wire with good corrosion resistance and electrical conductivity. Non-magnetic. |

Nickel Alloys

| Material | Commercially Available Specification | Nominal Chemistry | Density (lb/in3) | Minimum Tensile Strength (psi x 106) | Modulus of Elasticity (E)(psi x 106) | Modulus in Torsion (G)(psi x 106) | Maximum Operating Temperature | Description & Primary Use |

|---|---|---|---|---|---|---|---|---|

Hastelloy (C276) |

ASTM B574 | Ni 51.0 - 63.5%, Cr 14.5 - 16.5%, Mo 15.0 - 17.0%, Fe 4.0 - 7.0% | 0.32 | 100 - 200 | 30.7 | 11.8 | 700 °F | Good corrosion resistance in chemical process environments. Known for excellent resistance to sulfur and chloride compounds. Useful in marine and waste treatment industries. |

NiSpan C |

AMS 5225 | Fe 45.0 - 51.0%, Ni 41.0 - 43.5%, Cr 4.9 - 5.75%, Ti 2.25 - 2.75%, Al 0.3 - 0.8% | 0.29 | 150 - 190 | 24.0 - 29.0 | 9.0 - 10.0 | 150 °F | Special alloy that is heat-treatable to have a constant modulus over a range of operating temperatures. Material is not stainless and is magnetic. Typically used in timing devices, weighing and geophysical instruments. |

Elgiloy |

AMS 5833 | Co 39.0 - 41.0%, Ni 15.0 - 16.0, Cr 19.0 - 21.0%, Fe 15.0 - 18.0% | 0.30 | 270 - 300 | 32 | 12 | 850 °F | Cobalt-Nickel alloy known for strength and non-magnetic qualities. Excellent corrosion resistance, good for acetic acid, ammonium chloride, citric acid, sodium chloride and sodium sulfite. Material is precipitation hardened after spring fabrication to achieve desired properties. |

Inconel X750 |

AMS 5698 / 5699 | Ni 70.0 min%, Cr 14.0 - 17.0%, Fe 5.0 - 9.0% | 0.30 | No. 1 Temper: 155 Min, Spring Temper: 180 - 220 | 31 | 12 | 750 - 1100 °F | Better strength over Inconel 600. Material is precipitation hardened after spring fabrication to achieve desired properties. No. 1 Temper provides better heat resistance. |

Inconel 718 |

ASTM B637 | Ni 50.0 - 55.0%, Cr 17.0 - 21.0%, Fe 11.0 - 24.0% | 0.30 | 210 - 250 | 29 | 11.2 | 1100 °F | Better strength and heat resistance over Inconel 600. Material is precipitation hardened after spring fabrication to achieve desired properties. |

Inconel 600 |

ASTM B166 | Ni 72.0 min%, Cr 14.0 - 17.0%, Fe 6.0 - 10.0% | 0.31 | 140 - 185 | 31 | 11 | 700 °F | Good corrosion resistance and mechanical properties at moderately elevated temperatures. Also good for cryogenic applications. Used in chemical processing, heat-treating, and aerospace industries. |

Plastic Composite

| Material | Notes | Maximum Operating Temperature | Description & Primary Use |

|---|---|---|---|

Ultem |

A thermoplastic polyetherimide (PEI) resin and a trademark of SABIC Innovative Plastics IP BV. Ultem is naturally amber colored. Lee Spring uses custom resin blends of six color-coded strengths. | 340 °F | Excellent chemical resistance and thermal properties. Non-magnetic with very low flammability. |

.png)

Sign Up/Log In

Sign Up/Log In

蘇公網(wǎng)安備32059002002461號(hào)

蘇公網(wǎng)安備32059002002461號(hào)